Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.

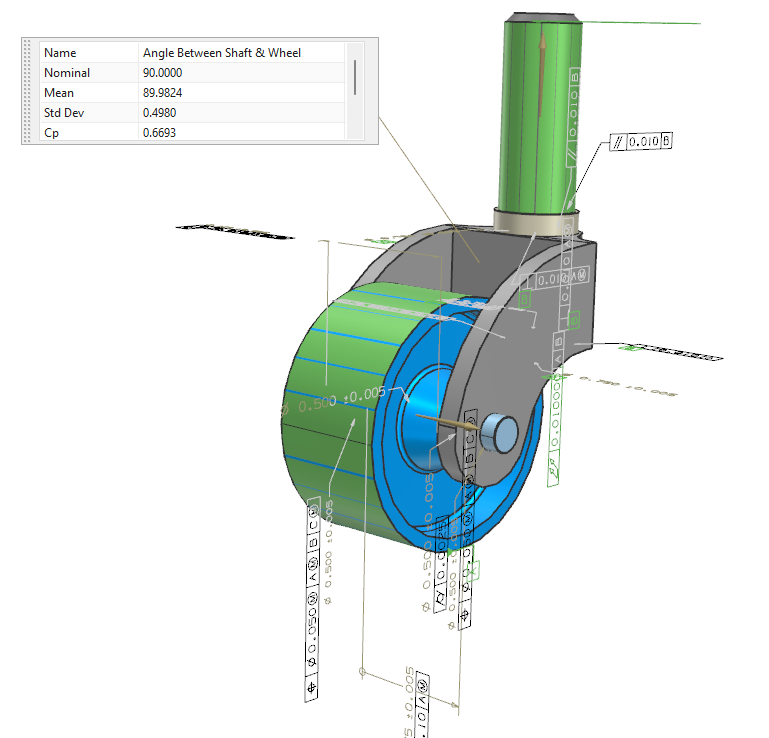

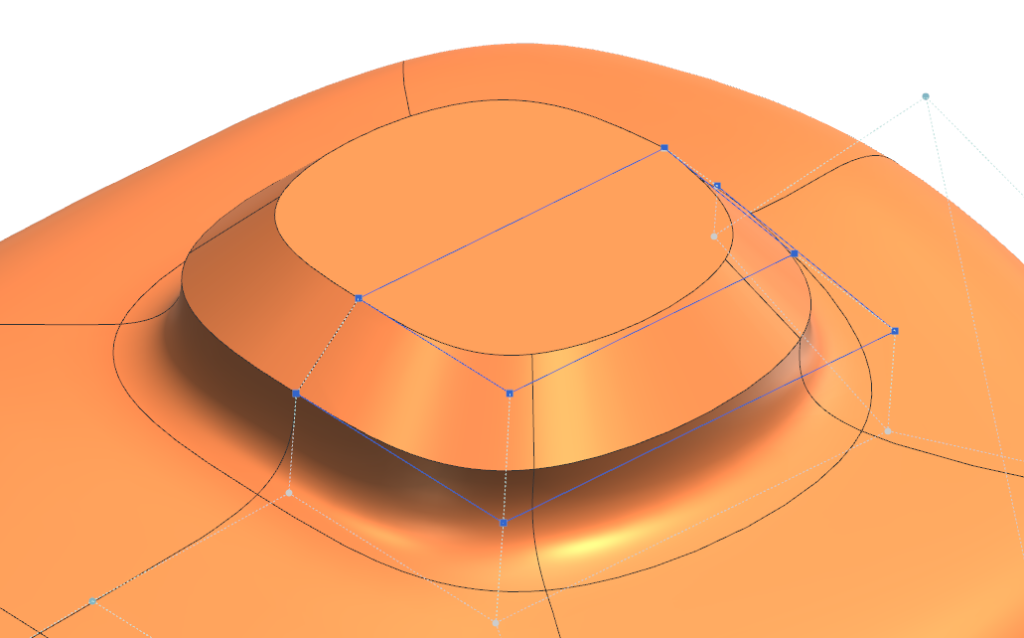

In our latest NX™ software Tips and Tricks video, we dive into the powerful capabilities of the Chamfer Cage tool within Realize Shape. This video showcases how to efficiently refine and polish subdivision bodies using symmetric modeling techniques. We explore the tool’s different continuity options for edge treatment, from smooth flowing transitions to precise chamfers, and demonstrate how these features can help achieve professional-grade surface quality. Whether you’re new to Realize Shape or looking to enhance your subdivision modeling skills, this video provides valuable insights into streamlining your workflow while maintaining design precision.

Check out the video below or scroll down to learn more about Chamfer Cage on Subdivision Bodies.

What is Realize Shape?

Realize Shape is a powerful subdivision modeling environment within NX that bridges the gap between conceptual design and detailed engineering. This innovative toolset enables designers and engineers to create, modify, and refine complex organic shapes with ease and control. By combining intuitive design tools with precise control mechanisms, Realize Shape offers a unique approach to creating sophisticated surface geometry that maintains both aesthetic quality and engineering integrity.

Unlike traditional CAD modeling, Realize Shape uses subdivision surfaces, a modeling method that allows for the creation of smooth, flowing forms through the manipulation of a simplified control mesh. This approach makes it particularly effective for designing products that require both aesthetic appeal and engineering precision. The environment provides us with the flexibility to make broad form changes while simultaneously maintaining the ability to focus on fine details, offering a level of control that traditional surface modeling often struggles to achieve.

Symmetric Modeling

Symmetric modeling is a fundamental feature in Realize Shape that significantly enhances our workflow efficiency when working with symmetrical designs. Instead of manually replicating changes across both sides of a model, this powerful capability automatically mirrors our modifications in real time. This not only saves valuable design time but also ensures perfect symmetry throughout the development process. For complex organic shapes and detailed surface refinements, this automatic mirroring becomes particularly valuable as it eliminates the potential for inconsistencies between sides.

When setting up symmetry in Realize Shape there are two primary approaches. We can create a datum plane through the Construction group, which is particularly useful when the symmetry plane needs to be referenced later in the design process. Alternatively, the symmetry plane can be established directly through the Start Symmetric Modeling window, where we can either create a new plane or select an existing one. Once the symmetry plane is defined, we can focus our attention on refining one side of the model, knowing that our changes will be perfectly replicated on the opposite side. This approach allows for more focused attention to detail while maintaining balanced design integrity throughout the model. The flexibility in establishing symmetry planes, combined with the automatic mirroring of design changes, makes this an essential part of effective subdivision modeling workflow in Realize Shape.

Chamfer Cage on subdivision bodies

The Chamfer Cage tool provides enhanced control over edge treatments in subdivision bodies while preserving the organic nature of our designs. The intuitive cage structure makes it easy to manipulate multiple edges simultaneously, offering precise control through a clear visual framework. This interactive approach streamlines the refinement process, allowing us to achieve consistent, high-quality surface transitions throughout our model.

One of the tool’s key strengths lies in its versatility through different continuity options. When selecting the smooth continuity setting, we can create flowing, natural transitions that seamlessly blend between surfaces, perfect for organic shapes and aesthetic designs. Alternatively, the sharp continuity setting delivers precise, mechanical-style chamfers that maintain clear, defined edges. This flexibility makes the chamfer cage tool valuable across a wide range of applications, from consumer products to industrial design.

Chamfer Cage’s efficiency becomes particularly evident when working with complex models. We can select and modify multiple edges simultaneously, applying consistent chamfer values across our design. Combined with symmetric modeling, this capability allows us to rapidly refine our models while maintaining professional-grade surface quality. The ability to easily adjust and fine-tune these modifications at any point in the design process ensures that we can iterate and explore different options without compromising our workflow or design intent.

Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.