Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.

Coatings are used throughout almost every industry and for a variety of reasons. This can include protection from the elements, increased strength and durability, and creating an enhanced cosmetic appearance for product designs. Be sure to follow along with our Tips & Tricks video as we showcase a few helpful tips below…

Let’s dive in!

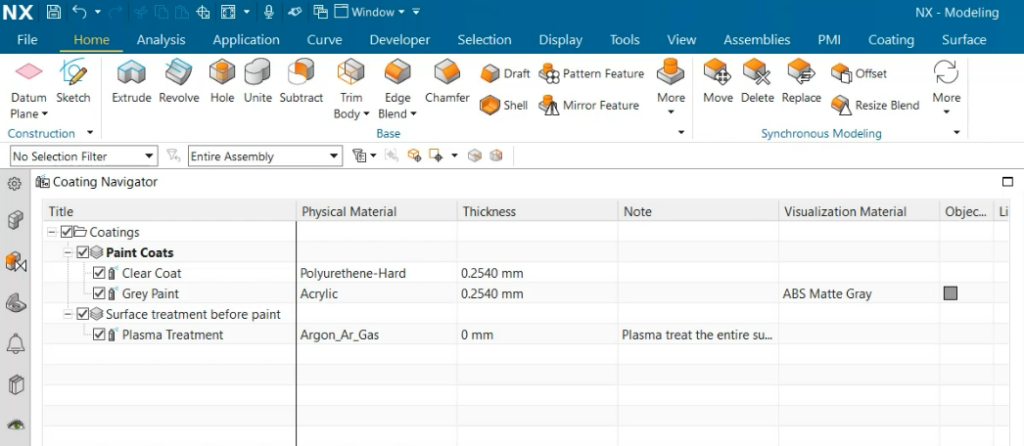

Open the Coating Navigator to explore the coats applied to parts and assemblies

When working with multiple people on a design, there can be times when you need to find out information about a component that you may not have worked on personally. In this instance, the quickest way to catch up on information for your surface treatments is to begin by opening the Coating Navigator.

In the Coating Navigator, the names of each layer can be found—along with the associated physical materials, coating thicknesses, notes, and a variety of mass properties for each layer. This is an excellent tool to help visualize all the coating stacks and the coating layers that are used in your surface treatments. Another key benefit of the Coating Navigator is that you can easily identify if a coating material is created as a non-geometric component, which can be useful when evaluating product mass properties.

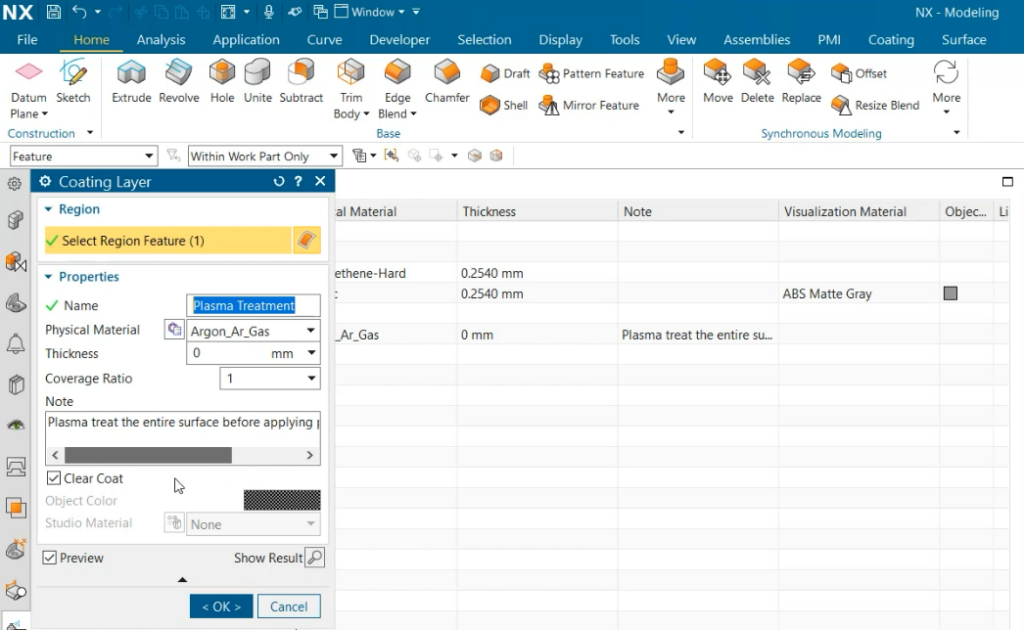

Double-click on a Coating Layer within the Coating Navigator to view more information

If you need to take a deeper look at any individual surface treatment, you can double-click on the coating layer within the Coating Navigator. The original window that was used to create the layer will reopen and include specifics such as if the treatment should be applied as a clear coat, as well as the coverage ratio of the coat. From this window, you’ll also be able to edit, rename, or even delete the layer depending on your design needs.

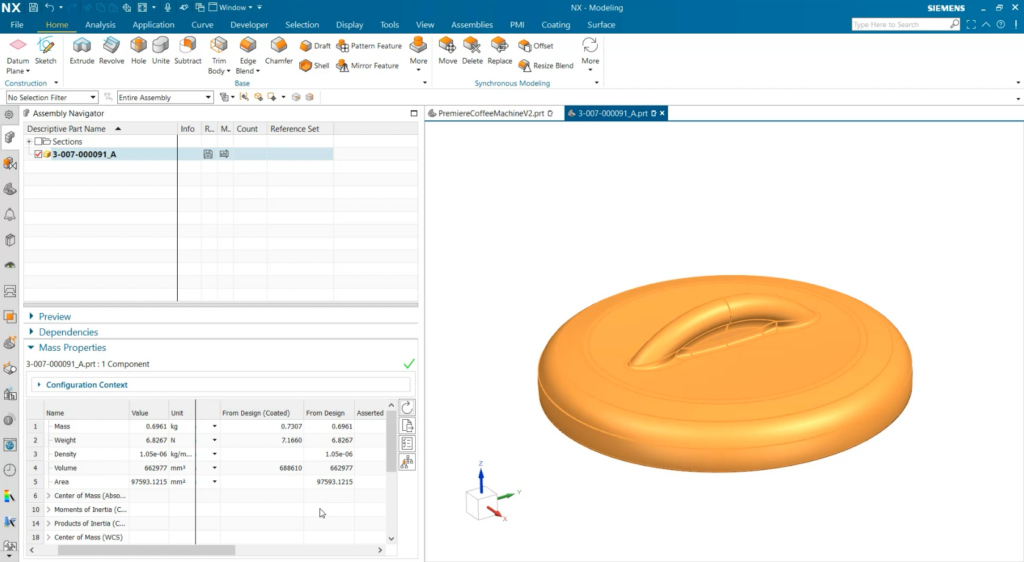

Investigate changes to product mass properties within the Assembly Navigator

The last tip we’ll cover to find information about your surface treatments is to simply open the Assembly Navigator. From here, it’s easy to see if any non-geometric components were applied in the coating layers. Furthermore, the Mass Properties tab inside of the Assembly Navigator can be reviewed to assess the overall impact of the coats that have been applied. This includes layer data such as mass, weight, density, volume, area, and more.

Within the Mass Properties tab, you’ll also find a column dedicated to showing the updated properties compared to the original properties prior to the application of surface treatments. This can be helpful in assessing if the final use of the product has been impacted by any of the coating layers.

Conclusion

Thanks for following us into the new year to learn more about the December 2023 release of NX. We hope that you’ll continue to explore how NX Coatings can help speed up your workflows and validate designs. And, as always, reach out and let us know if there are any NX topics you’d like us to cover in the future!

Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.