Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.

NX X

It’s important to note the ever changing demands of the consumer in the modern world. All whilst ensuring there is no compromise on functionality, quality, and availability of features.

This is something we recognize here at Siemens. Introducing NX X; the cloud based version of NX. NX X is a comprehensive SaaS solution that lets you access NX’s full computer-aided design (CAD) capabilities with all the associated flexibility, data security, and scalability benefits. Additionally, take advantage of connected workflows within your organization, whilst simultaneously tapping into IT expertise.

Built on traditional NX architecture, zero translation of data is required, The result? A reduction in delays, errors and reworks in the design cycle.

Be sure to check back for updates throughout 2024 on NX X and how it can benefit your workflows.

NX Immersive Explorer

Let’s take a look at the new capabilities added to this release around design reviews. Introducing NX Immersive Explorer; an application that enables you to visualize and review CAD data in an immersive and interactive VR or desktop experience. Explore the right designs before committing resources to physical prototyping, all within a fully immersive environment.

Key capabilities within NX Immersive Explorer

NX Immersive Explorer is designed in a way to give you complete control over how you operate within your design review. Handheld controllers are used to control everything within your virtual reality review, and both large and small scale models are supported. An intuitive tablet user interface displays commands that are typically used to review a CAD model, ensuring the critical features you need are at the click of a button. These are just some of the capabilities that are at your disposal within NX Immersive Explorer:

Applying and changing scenes for your model Applying a scene is a great way to see how your model will look in different real-world scenarios. Take an automotive vehicle for example. It would be great to see how your vehicle would look in a car showroom, and get a real sense of how potential customers will see it. Similarly, seeing the vehicle in a more natural environment can go a long way to influencing the consumers purchasing decision.

Exploring your environment

With NX Immersive Explorer, it’s easy to navigate around your environment to get a true sense of scale, or to change your perspective on the model. Use the teleportation tool to move around the scene, or change your elevation to see the environment in its totality. It’s a handy feature to use within your design review, irrespective of the size of your models and environments!

Manipulating your model

You can interact with every single part of your model to conduct your design reviews. Grab, select, hide, view, rotate or scale any part. Additionally, use the section tool to view a cross section of your model and get a sense of internal parts.

Design review tools at your disposal

It’s essential to capture design intent when you’e conducting your design review. So, you can take measurements of parts if there are inaccuracies that need to be rectified. Additionally, you can draw annotations, add sticky notes, and capture snapshots. These tools are essential in communicating design ideas across functions, and ensuring your designs are refined to a level that you’re happy with.

NX for Concrete Design

Next, let’s shift our attention to BIM, and what we’ve been focusing on for this release. Trends in the industry are shifting toward the ability to create complex digital twins, with a need for design collaboration in a sustainable manner. Additionally, the need to access data, anywhere, and at any time is becoming even more important.

It’s always important to think about the challenges facing industries across the globe; the BIM space is no different. Companies continue to be prone to project delays and cost overruns, whilst labor shortages are becoming more frequent. Furthermore, inefficient design processes and data inoperability continue to exacerbate the problem. Throw in current volatility of the global market creates the perfect storm of issues that companies are facing.

NX for Concrete Design

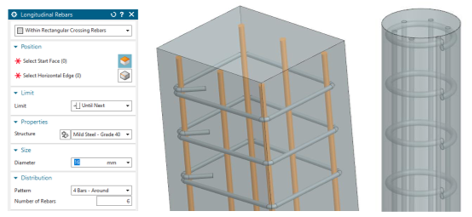

Introducing NX for Concrete Design, an advanced 3D parametric design tool enabling designers to quickly create reinforced design elements. It’s a new multi-disciplinary design tool that is built on the NX foundations, and enables a collaborative design environment to eliminate mistakes that arise when design teams are silo’d. On top of this, Concrete design is a managed design environment, ensuring design changes are propagated through the design cycle and are always up to date.

See NX for Concrete Design in action

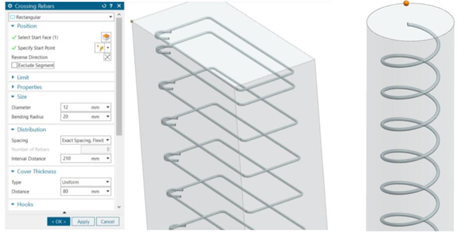

Key functionality we want to showcase is the ability to create re-enforced concrete design with NX. You can easily create rebar stirrup and ties (aka Crossing Rebars) as well as longitudinal bars associatively within the concrete form. There’s support for rectangular and cylindrical precast elements, whilst crossing Rebars are generated based on the concrete shape. Additionally, there are flexible size and spacing options for Crossing Rebars, whilst hook end conditions support standard 90˚, 135˚, 180˚, and

user defined angles.

NX Corrosion Analysis

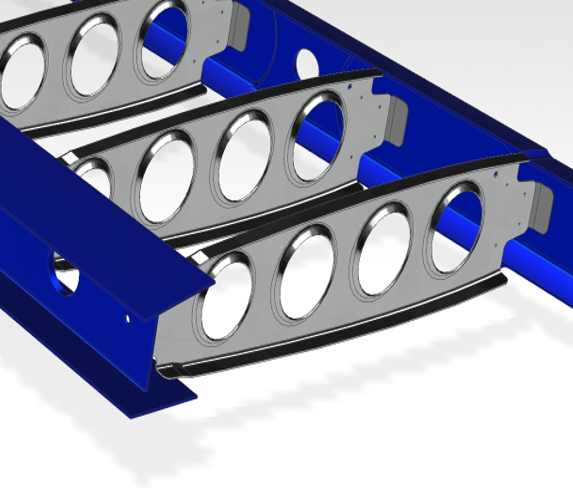

Let’s shift our attention to NX Corrosion Analysis – a new add-on module introduced in this release of NX. This new functionality provides corrosion analysis of component parts in an assembly based on their proximity, assigned materials, and coatings. It will predict the corrosion risk rate based on the galvanic properties of the assigned materials by using the latest industry approved methods. Finally, results are displayed both graphically and textually to inform users in an easy to understand report.

NX Corrosion Analysis in action

This new functionality will determine which components that come into contact with one another are most likely to corrode. Additionally, you’ll be able to make use of standard defined component materials, evaluate the impact of assigned coatings, and choose from environmental conditions to evaluate within. The functionality comes equipped with the latest galvanic corrosion assessment method provided by Cordessa Dijnn, and adheres to MIL-STD-889D.

When looking at the results, face pairs that touch will be evaluated for corrosion risk, with a galvanic corrosion rate assigned. Upper and lower limits can be set by you, and you can study interference zooms by focusing on a particular area. Finally, you’ll have the ability to generate a comprehensive report that includes detailed corrosion rate factors.

The benefits of NX Corrosion Analysis

We’ve introduced NX Corrosion Analysis, but what benefits can be gained from using this new tool? Well, you’ll be able to identify a lack of coating or material specification in your CAD models, and identify where the use of corrosion barriers maybe needed. Additionally, crucial information can be fed back to the engineering team, so that ‘what if’ studies around changing material, coating or design parameters can be performed. It’s a shift left approach to analyzing corrosive materials; you can easily identify if areas in the design require further study, ensuring your engineering workflows are as efficient as possible.

Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.