Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.

By Jimmy Costello

Our latest NX™ software Tips and Tricks video demonstrates a useful new sheet metal tool for creating and controlling variational flanges.

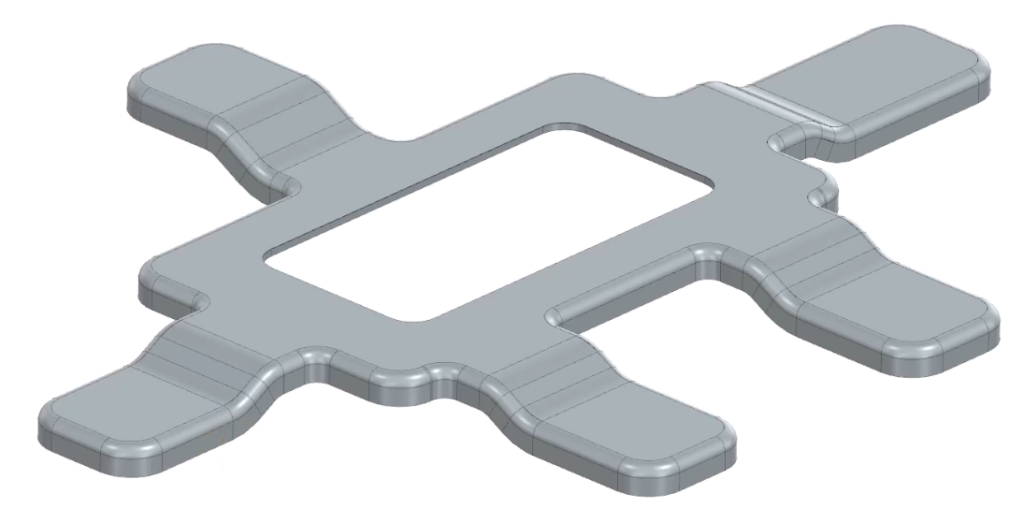

Released in December 2023, the variational flange command is a new tool that can be used to create flanges on any tangential edges. These flanges will extend to non-coplanar edges, with the options to vary flange length and angles. Watch the Tips and Tricks video below.

Introduction to Sheet Metal

Sheet Metal is an application within NX that provides an environment for the design of sheet metal parts used in machinery, enclosures, brackets, and other parts normally manufactured with a brake press. The Sheet Metal application offers a number of options when it comes to optimizing your parts and designs. Some of these capabilities include:

- Using basic features such as flanges, tabs, and jogs to create uniform thickness parts

- Taking solid models that are designed in the Modeling environment and then converting it to a sheet metal part

- Importing, cleaning up, and converting non-sheet metal parts to a valid sheet metal part

- Exporting flat pattern data of sheet metal parts to other applications

With the Sheet Metal application, there are a number of key benefits. NX offers a complete set of tools to create the sheet metal designs you need. These tools helps produce an accurate generation of flat patterns for downstream processes, and there are even advanced commands for non-linear and complex designs.

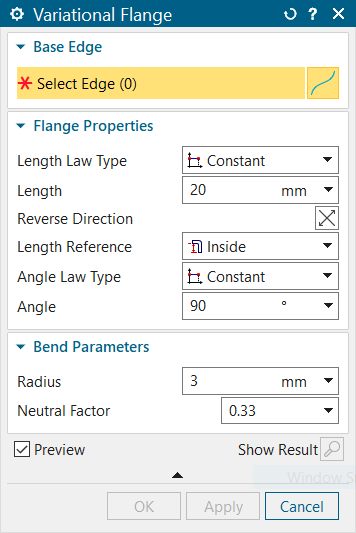

Customizing your variational flanges

One of the biggest benefits to the Variational Flange command is the wide range of options it offers. Drop-down boxes for length law type, length reference, and angle law type all make it incredibly easy to create flanges that fit your design requirements. Lets look at what each drop down box is for:

Length Law Type – This box lets you specify the law type for the length of the flange. There are two options here: Constant and Linear. The constant option lets you define a constant value for the length of the flange. On the other hand, linear lets you define a linear rate of change for the length of the flange from start to end.

Length Reference – This is where you specify the reference point for the web length of a flange. You can choose to measure from the inside intersection, outside intersection, pure web length, or from the tangency to the external bend.

Angle Law Type – Here is where you specify the law type for the angle of the flange. Like with the length law type, there are two options: Constant and Linear. The constant option will define a constant value for the angle, while the linear option defines a linear rate of change for the angle.

In addition to the flange property options discussed above, there are still more customization options. With the bend parameters, there is an option to set a neutral factor. The neutral factor is a number that depends on the properties of the material being bent. In simple terms, it is the ratio between the thickness of the metal being bent and something called the “neutral axis/line.” This neutral axis is the point on the part that is in neither compression nor tension. This value defaults to 0.33, but can be set anywhere between 0 and 1.

Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.