Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.

Additively manufactured spare parts will drive technological innovation and market growth, moving industries forward.

Pelagus 3D, a joint venture company of thyssenkrupp and Wilhelmsen, and Doosan Enerbility signed a memorandum of understanding (MOU) to advance the adoption of on-demand additive manufacturing (AM) in Korea’s maritime and offshore industries.

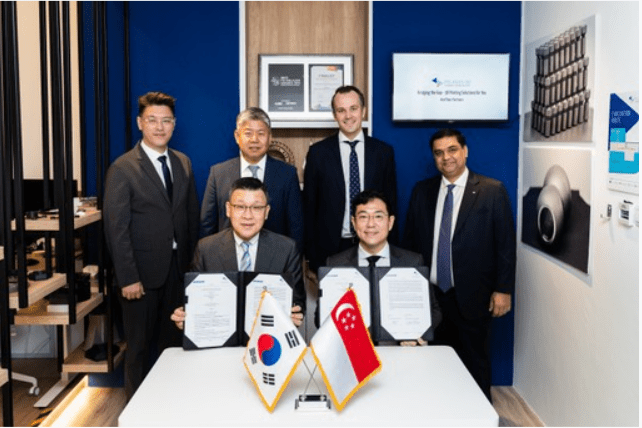

Photo Caption (front row L to R): Yongjin Song, Executive Vice President of Strategy & Innovation Head, Doosan Enerbility; Kenlip Ong, Chief Executive Officer, Pelagus 3D; (back row L to R): Hyunchul Cho, Head of AM Business Team, Doosan Enerbility; Huibom Lee, Vice President of Strategy & Innovation, Doosan Enerbility; Haakon Ellekjaer, Chief Commercial Officer, Pelagus 3D;Nakul Malhotra, Vice President of Emerging Opportunities Portfolio, Wilhelmsen Maritime Services, and Board of Director, Pelagus 3D

The MOU was signed by Mr Kenlip Ong, Chief Executive Officer of Pelagus 3D, and Mr Yongjin Song, Executive Vice President of Strategy & Innovation of Doosan Enerbility, in Singapore at Pelagus 3D’s headquarters.

This collaboration brings together Pelagus 3D’s engineering expertise in AM and in-depth maritime knowledge, along with Doosan’s Enerbility’s proficiency in the Original Equipment Manufacturer (OEM) spare parts industry.

During a three-year term, both parties will work together to enable OEMs in Korea to implement and adopt on-demand manufacturing, addressing key supply chain issues. Pelagus 3D will provide innovative additive manufacturing solutions, while Doosan Enerbility will facilitate the adoption of AM within the maritime OEM community.

“The MOU signing with Doosan Enerbility marks a pivotal milestone in creating a more resilient and efficient spare parts supply chain. This collaboration will drive technological innovation and deliver enhanced value to our network in Korea. The Pelagus Platform will ensure seamless integration and accelerate adoption of AM among OEMs and end users,” said Kenlip Ong, Chief Executive Officer, Pelagus 3D.

Under this agreement, Pelagus 3D and Doosan Enerbility will also collaborate on a variety of initiatives including AM technology exchanges, pilot testing, and adoption of the Pelagus Platform.

The Pelagus Platform facilitates ease of acquiring and producing on-demand spare parts through leveraging digital warehouse management and order fulfilment capabilities. It connects OEMs and end users to manufacturing partners worldwide.

“Doosan Enerbility has been demonstrating the technological excellence and economic feasibility of its AM business to its wide range of customers in not only the power generation sector, but those in the defence and aerospace sectors as well,” said Yongjin Song, Executive VP of Strategy & Innovation of Doosan Enerbility. He added, “Under this partnership, we plan to do our utmost to further promote the growth of the AM business and develop new markets.”

The project will foster innovation and drive continuous improvement in AM spare parts development, bringing further insights into potential partnerships and opportunities in the industry. It streamlines processes and improves efficiency across the manufacturing value chain, connecting the Singapore and Korea markets.

Pelagus 3D is committed to the continued expansion and adoption of AM spare parts in the maritime and offshore industry. To learn more about Pelagus 3D, visit pelagus.com

About Pelagus 3D:

Pelagus 3D is an on-demand digital manufacturing partner for the maritime and offshore industry. A joint venture company of thyssenkrupp and Wilhelmsen, Pelagus 3D leverages on additive manufacturing to ensure the availability of on-demand spare parts. With our incomparable ecosystem of global partners, a secured digital Pelagus platform, and 3D design expertise, Pelagus 3D is focused on helping customers ensure connectivity and continuity in operations without interruption. Know more about Pelagus 3D at Pelagus.com.

About Doosan Enerbility:

Doosan Enerbility has been providing specialised products and services for power plants to 40 countries around the world for over 60 years. At Doosan, we have the technology to manufacture the main components of power plants, such as turbines, generators, nuclear reactors, and steam generators. Having now expanded into the services business, we also offer performance upgrades and life cycle extensions for power plant equipment and implement various environmental control systems and digital solutions to help reduce the emission of pollutants. Our business focus is now shifting toward clean energy solutions, such as gas turbines, renewable energy, hydrogen energy, and SMRs. We are also actively expanding into new areas, such as additive manufacturing, battery recycling, and digital solutions businesses.

Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.