Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.

Mastercam CAD/CAM software is a self-contained, fully-capable NC-coding program for manufacturing applications. Within its main solution products, like Mill and Lathe, most users are able to program any part that comes across their desk. In some cases, however, processes can be streamlined or precision boosted with outside help. That’s where Add-Ons come into play. A Mastercam Add-On is a software extension that delivers additional Mastercam functions. Each has its own specialized function and is designed to help with one key machining application. This blog is the first in a series of two that will explain each of Mastercam’s many Add-Ons.

Mastercam Multiaxis

One of the most popular Add-Ons to the Mastercam suite is the Multiaxis solution. It provides the advanced control users need to get more out of their 3-axis machines than they would with conventional machining. It also directs 4- and 5-axis simultaneous machining on multiaxis units. Multiaxis’ pre-defined strategies take charge of programming immediately, applying high-precision cutting patterns to the part automatically. For example, its Dynamic and Accelerated Finishing technologies are enhanced motion strategies. They remove great quantities of material at exceptional rates, while still producing outstanding surface finishes. Multiaxis also calculates the optimal tool tilt axis angles to avoid gauges and stay within machine tool limits. However, every aspect is highly customizable and open to user tinkering.

The Multiaxis Add-On excels in situations with complex, free-form components, with critically tight tolerances, or with tight deadlines. All are becoming more common in the aerospace, automotive, and consumer goods industries. Multiaxis reduces the number of setups required to finish a part. This in turn smooths the transitions between surfaces, speeds production, and reduces blemishes caused by numerous refixturing procedures. Because parts programmed with Multiaxis need so little human interaction, many are safe to run lights-out.

Productivity+

Productivity+ is a solution designed for increasing precision and accuracy. It employs a Renishaw measuring probe on the machine tool to record and report fixture offsets, tooling offsets, and program orientation. It then goes further and rolls that data into advanced in-process control tasks like component set-up, critical feature verification, process development, and dimension and tolerance analysis. Productivity+ can also help with the predictive process.

This Add-On works best in shops that want to boost production with unattended machining. Because of the added security and control provided by Productivity+, users are able to step away from machines and run them lights-out.

Port Expert

This Add-On was expressly designed for cylinder head porting. It simplifies the programming process by applying specialized cutting techniques based on the selected geometries’ data. The toolpath motion can start at either end of the port or meet in the middle, depending on user preference. Where the cuts meet, integrated linking motion ensures the transition is seamless. Extra care is given to the finishing process. Finishing motions can run parallel or perpendicular to the direction of flow through the cylinder, but both produce superior surface finishes. Port Expert is stock-aware, avoids collisions autonomously, and offers automatic tool tipping.

Port Expert is most often used for programming cylinder head ports for high performance engines, but it can also be invaluable in complex tube work, for deep pockets, and for surface patching cylindrical parts. Most aerospace applications would benefit from its addition. To run Port Expert, users simply define their geometries, configure their tool and machining parameters, and let the Add-On software run its calculations to find the best machining approach.

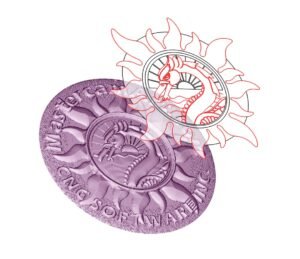

Mastercam Art

Turn two-dimensional digital graphics into three-dimensional designs with Mastercam Art. This Add-On accepts 2D sketches, clip art, photos, and CAD data in varying forms: most often, JPG, TIFF, and raster-based files. It then translates the visual’s data into toolpaths that can be done on almost any CNC machining unit with Mastercam Art’s specialized toolpaths. It is the perfect solution for adding logos or aesthetically-pleasing features to any part.

Mastercam Art excels whenever a part calls for relief designs. Parts that require engraved serial numbers, name plates, and coasters with beautiful designs are all textbook applications. Mastercam Art automates most of the programming process and will apply cutting techniques in accordance within the user’s preset restrictions. When users want more control, they can add, remove, intersect, and blend organic forms with simple mouse clicks.

Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.