Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.

ASCO Software is a leading developer of CAD/CAM software for sheet metal manufacturing and an active partner in the Siemens partner program with a focus on solution integrated with Siemens Solid Edge. ASCO Data combined with Alma in 2017 to form a leading supplier of CAD/CAM software for sheet metal design and manufacturing.

ASCO software solutions control many technological processes for sheet metal manufacturing and machine welding, from standard machines to more complex installations. They deliver immediate measurable gains and are designed to provide excellent user experience. Integration with a manufacturer’s existing CAD, PDM, CAM and ERP processes is a key capability, and ASCO software is integrated into Solid Edge for versions from Solid Edge 2020 onwards.

ASCO software consist of a series of modules with the following areas of focus:

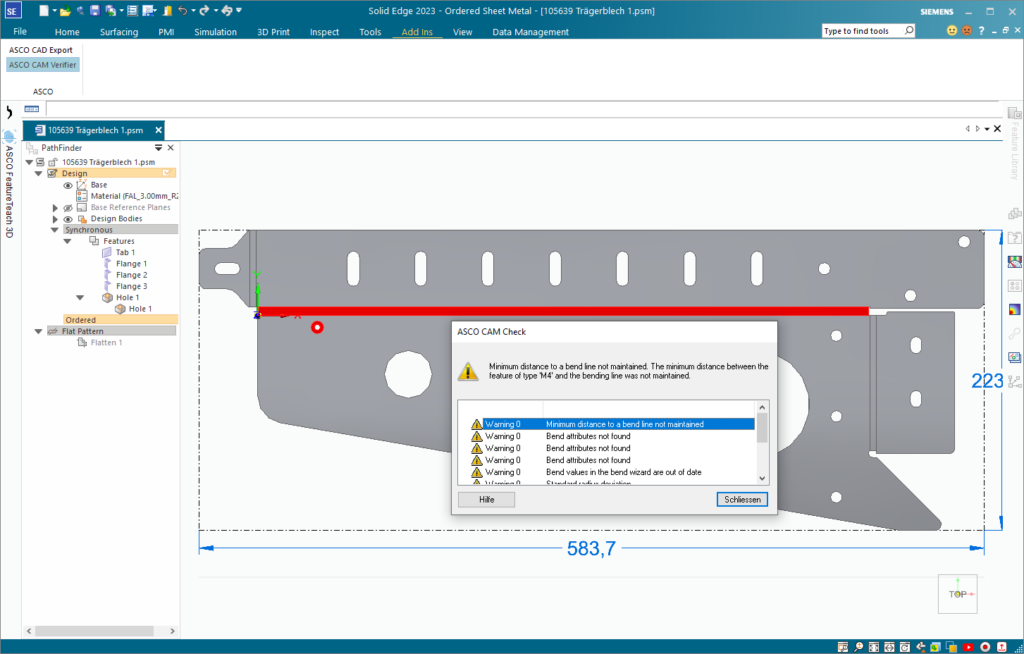

- Production-ready design supports CAD users with digital design guidelines enforcing key parameters that ensure quality and manufacturability. ASCO software inspects sheet metal parts quickly and effectively during the design process in Solid Edge and ensures they comply with company-specific manufacturing capabilities. The user trains the system with company standard features such as holes, louvres and threads. These features are automatically recognized during the design-through-manufacturing process.

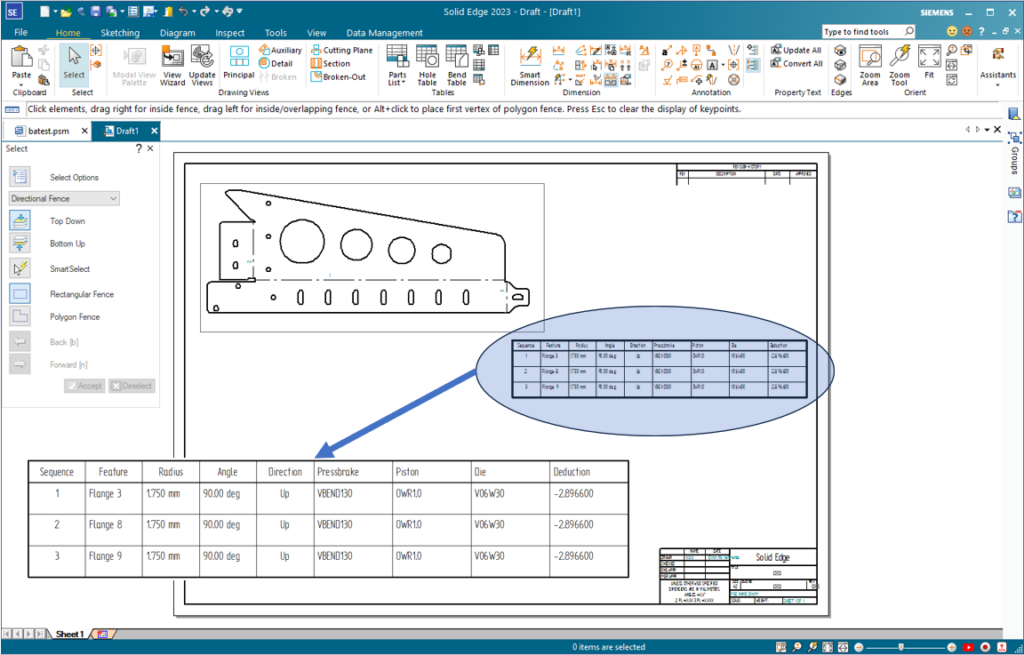

- Production-oriented processing ensures assignment of company specific bending parameters during the design and manufacturing preparation processes. The bend features of the model are displayed in the Solid Edge Drawing with key information about each individual bend. The user selects the tool to be used to create the bend from a company specific database. This only displays the tools that are permissible for the designated material and thickness.

- Design and manufacturing feature recognition supports automatic recognition of features used for sheet metal operations including forming, threading, and beading. The software automatically interprets features such as louvres, dimples, and threads, and special types of processing (cutting, engraving, fits, etc…) and generates the correct specifications for NC toolpath creation.

- Automatic determination of machine time cycles at post-processor level for operations including bending, cutting, milling, and punching.

An example of a manufacturer who is using Solid Edge for mechanical design together with ASCO software for sheet metal manufacturing is BRÜCKNER Maschinenbau GmbH based in Germany. BRÜCKNER designs and manufactures machinery for the coating and finishing of textiles. As you can see in the image below, the textile machinery manufactured by BRÜCKNER includes many large-scale sheet metal components and assemblies. BRÜCKNER uses several components of the ASCO software integration into Solid Edge including CAM output and verification and a bend wizard. They have also integrated the output and management of machine ready DXF files using Siemens Teamcenter. BRÜCKNER is supported in their use of Solid Edge by their local channel partner in Germany, Solid System Team. A case study for BRÜCKNER (in German) is on the SST website.

Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.