Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.

In the late 1980s, three innovators—Scott Crump, Chuck Hull, and Carl Deckard—embarked on separate quests to push the boundaries of design and manufacturing. Scott invented Fused Deposition Modeling, Chuck pioneered stereolithography, and Carl created Selective Laser Sintering.

Their individual journeys led to a collective impact that reshaped the world, leaving an indelible mark on design, prototyping, and production. Today, their contributions are utilized across various industries, from consumer goods to space exploration. These three groundbreaking technologies collectively converged to create what we now know as 3D printing.

This article will focus primarily on stereolithography.

What is Stereolithography, and How Does it Work?

Stereolithography is a 3D printing method that utilizes a laser to cure a photosensitive (sensitive to UV-light) resin. Engineers, designers, and manufacturers use it to craft detailed prototypes, intricate models, and functional parts with high accuracy and smooth surface finishes.

Like all 3D printing methods, stereolithography begins with a 3D model of the object you want to create. This model can be created using CAD software (like SOLIDWORKS) or by 3D scanning an existing object. The 3D model is then digitally sliced into thin layers (typically 50 – 200μm (0.05 to 0.2 millimeters)). For reference, a standard sheet of copy paper is around 100μm thick.

A vat of photosensitive liquid resin is then heated to a specific temperature and then a laser is used to trace the cross-section of each layer on the surface of the resin. The resin is instantly hardened where the laser touches while the rest remains liquid. The build platform is then lowered, and a new thin liquid resin layer is applied.

The process is repeated until the entire object is created. The object is then removed from the vat of resin and post-processed. Post-processing may involve cleaning the object, removing supports, and applying a finish.

- PostProcess Technologies DEMI 4000 Series is a scalable post-printing solution for high-volume stereolithography production. Check out the full lineup here.

Stratasys Neo: A Paradigm Shift in Stereolithography Technology

Seizing an Opportunity: Post-Patent Innovation

Between 2013 and 2015, several of the initial stereolithography patents expired. This marked a pivotal moment for 3D printing, opening the door to unlocked innovation of a proven technology. Recognizing this opportunity and fueled by a team of brilliant minds, Stratasys strategically expanded into stereolithography, dedicating years to refining and improving the technology. Their approach and strategic acquisitions ultimately culminated in creating the revolutionary Neo series.

Elevating Reliability and User Experience

The Neo series from Stratasys represents a game-changing advancement in stereolithography technology that redefines the user experience. Crafted by a team of engineers who intimately understand the challenges with legacy stereolithography printers, the Neo presents a comprehensive solution to enhance reliability, productivity, and overall performance.

Engineering Excellence: Where Simplicity Meets Reliability

At the heart of the Neo is a commitment to engineering excellence. Stripping away unnecessary complexities, the Neo boasts a simplified design incorporating only the best components. This fusion of simplicity and quality results in unparalleled reliability, ensuring that the Neo consistently delivers exceptional results, print after print.

Software Sophistication: Intuitive Control

Navigating the Neo is a seamless experience, thanks to its sophisticated but simple software interface. Engineered with user-centric design principles, the software offers intuitive control, robust reporting, and advanced traceability features. This ensures that users have complete oversight of their projects, from start to finish, with minimal effort.

Precision Personified: Delivering Quality

Part quality has always been a concern in 3D printing. The Neo nullifies these concerns with its precision and unmatched layer-to-layer repeatability. This translates into smooth surface finishes, drastically cutting post-processing efforts and elevating the fidelity of printed parts.

Open Resin Design and Materials: Unleashing Freedom

While some stereolithography systems restrict users to specific materials, Neo provides a unique freedom of choice. Users can select from a broad array of commercially available resins, tailoring their material selection to precisely match the needs of each individual project. This approach promotes efficiency, flexibility, and cost-effectiveness and breaks free from the constraints often imposed by closed material systems.

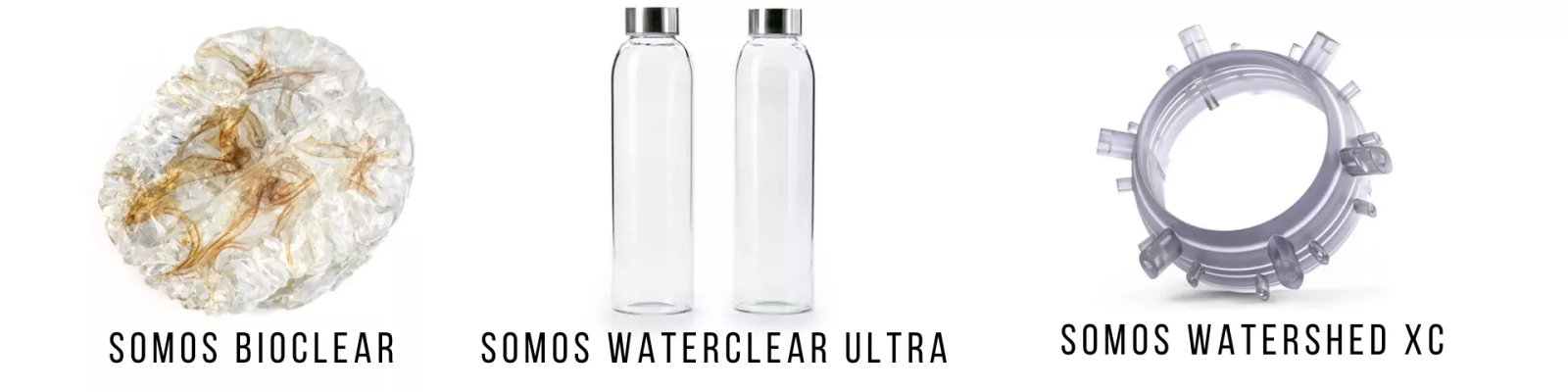

Precision-Crafted for Neo: Unveiling the SOMOS Resin Lineup

Stratasys’ SOMOS material lineup, designed to complement the Neo series, offers a variety of high-performance resins. These resins have unique qualities that extend the capabilities of stereolithography. With attributes like optical clarity, moisture resistance, durability, and heat tolerance, SOMOS materials become the driving force that turns your ideas into reality, embodying innovation and practicality.

Stratasys Stereolithography materials Somos BioClear, Somos Waterclear Ultra, and Somos WaterShed XC. View all here.

Elevating the Printer Platform: Form Meets Function

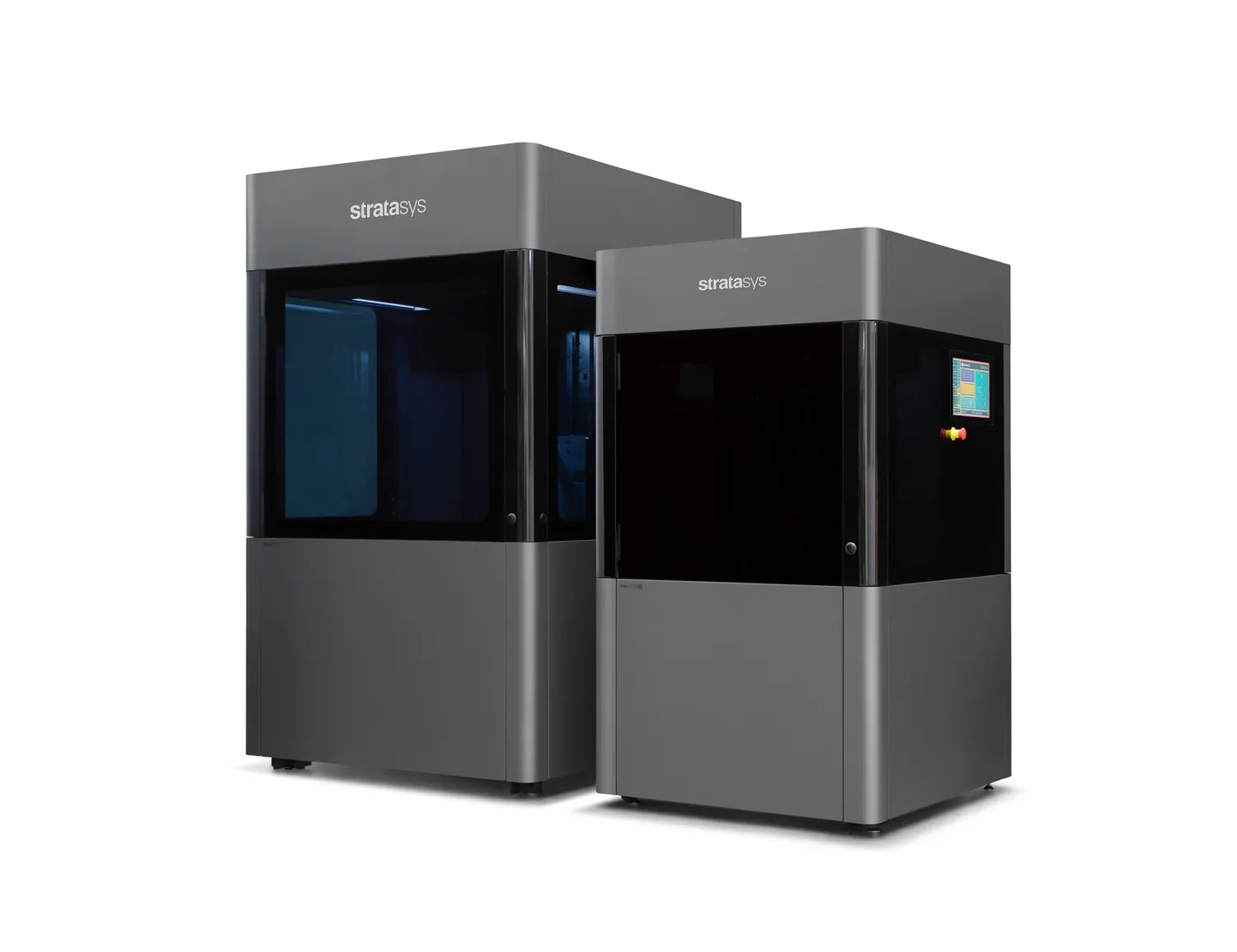

The Neo doesn’t just excel in performance – it also raises the bar in design. With a sleek profile, a smaller footprint, and a larger print platform, the Neo optimizes floor space while offering an expanded build area. Whether choosing the Neo800 for larger projects or the Neo450 for compact spaces, this lineup offers a solution to diverse applications while upholding uncompromising quality.

A Real-World Example: Reducing Prototyping Time by Up to 90%

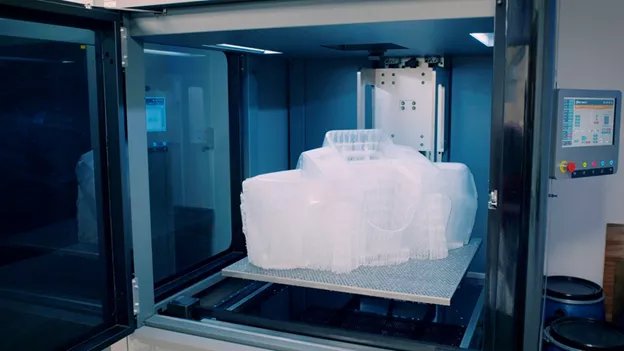

Paragon Rapid Technologies is an engineering support and product development company based in the UK. They’ve harnessed Stratasys’ Neo stereolithography 3D printers to generate functional prototypes, intricate models, and essential parts across various industries. The Neo technology integration has streamlined their production processes, yielding tangible results.

Neo800’s significant build area of 800 x 800 x 600 mm allows Paragon to produce large parts in one single print.

For instance, when faced with the urgent need for a prototype car bumper—a traditionally time-intensive process involving weeks of machining, post-processing, and tooling—Paragon adopted the Neo800 3D printer. The outcome was remarkable. The production time for the prototype car bumper was drastically reduced to just three days, representing a 90% decrease. This showcases how the Neo series contributes to efficient, rapid manufacturing and practical innovation.

Join the forum for Designers!

Your expertise is vital to the community. Join us and contribute your knowledge!

Join the Forum NowShare, learn and grow with the best professionals in the industry.